The Best Strategy To Use For Sheroz Earthworks

The Best Strategy To Use For Sheroz Earthworks

Blog Article

Sheroz Earthworks Fundamentals Explained

Table of ContentsSee This Report on Sheroz EarthworksEverything about Sheroz Earthworks5 Easy Facts About Sheroz Earthworks ExplainedThe 10-Minute Rule for Sheroz EarthworksThe Ultimate Guide To Sheroz EarthworksThe 5-Second Trick For Sheroz Earthworks

Today, Smart Building and construction Remote connects over 700 devices on jobsites to offices, conserving hundreds of hours previously invested by jobsite supervisors, surveyors and designers commuting from offices to jobsites. To summarise, the initial 10 years of Komatsu's intelligent maker control have actually been noted by a decade of unique advancement, regular knowing and growth with clients.

Here's to the following 10 years! Material produced in organization with Komatsu.

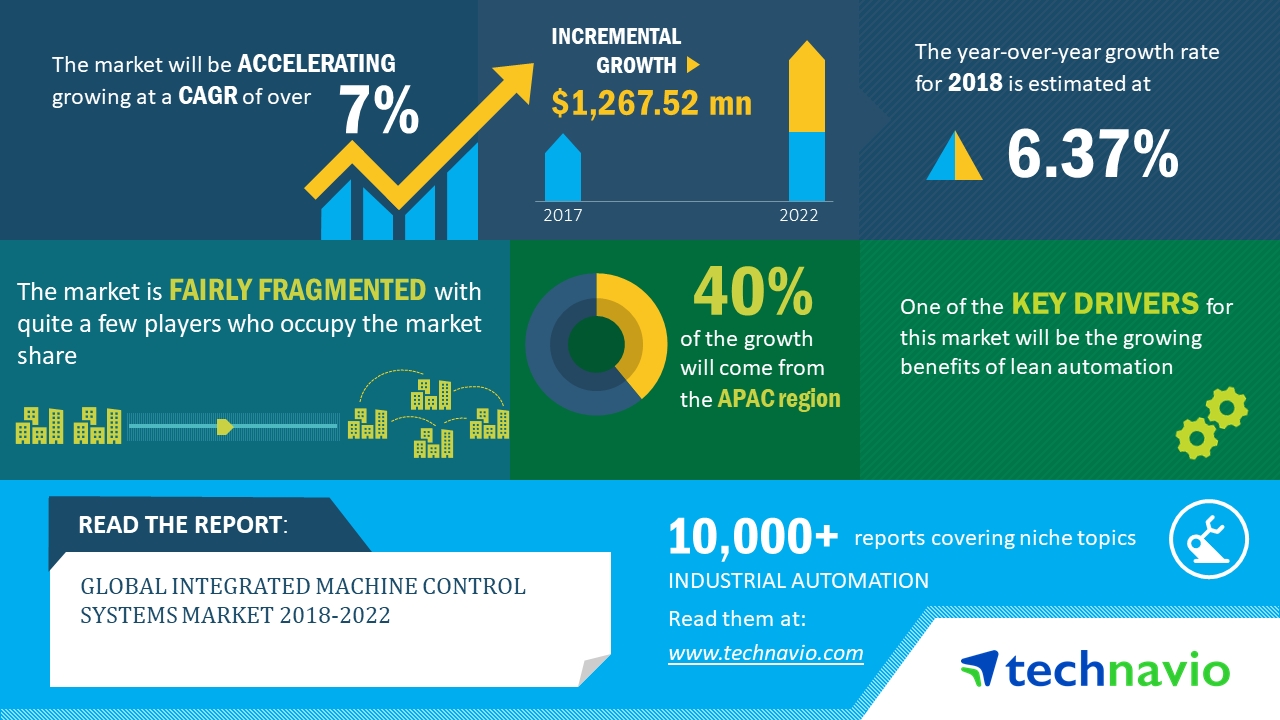

In the quickly progressing globe of construction, accuracy and performance are essential. 3D machine control, a system that uses GPS and other sensing units to guide machinery with identify precision, is changing the industry - https://pblc.me/pub/2669cbf4eae9a6. From its very early days of 2D assistance, this modern technology has actually progressed significantly, making tasks that when needed manual intervention now feasible with very little human input

At the core of any 3D equipment control system are GNSS receivers and antennas, catching satellite signals to establish the device's exact area. Onboard computers and control boxes process this information and connect with the machinery.

Fascination About Sheroz Earthworks

This consists of setting up GNSS receivers, adjusting sensing units, and setting up the maker control software - topcon gps. The magic of 3D maker control exists in its real-time information collection and handling.

User interfaces offer real-time updates on the device's position and required modifications, making certain precise control. Numerous variables affect accuracy, consisting of satellite signal high quality and sensor calibration. Techniques like Real-Time Kinematic (RTK) placing and Precise Point Positioning (PPP) boost precision, ensuring the greatest accuracy. In building, 3D device control is used for earthmoving, grading, paving, and excavation, ensuring jobs are completed to precise specs.

The Only Guide to Sheroz Earthworks

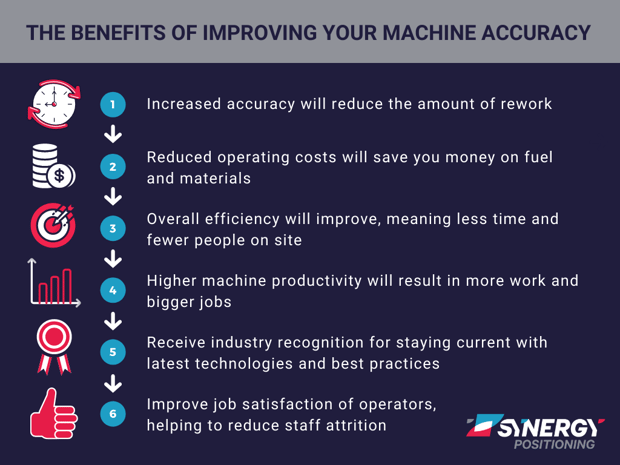

3D machine control significantly increases effectiveness by decreasing rework and reducing product wastefulness, causing much faster and extra economical project conclusion. The innovation guarantees every job is executed specifically as planned, causing continually premium job. Among the most compelling benefits of 3D device control is the substantial price savings it provides.

Fuel consumption is optimized because makers operate much more efficiently and avoid unneeded movements. Upkeep costs are additionally decreased, as the machinery experiences much less damage because of accurate procedure. Generally, these cost savings add to a more profitable profits for any job. By lowering human error and limiting direct exposure to hazardous atmospheres, 3D machine control enhances worker safety and security and decreases mishaps.

From construction you could try here to mining, this modern technology makes certain tasks are implemented properly and securely, reducing prices and improving end results. As innovations continue, the possibility for 3D maker control to even more boost performance and safety grows. Embracing this modern technology is crucial for industry experts seeking to remain competitive and achieve the highest possible criteria in their tasks.

The Main Principles Of Sheroz Earthworks

Discover the future of precision and effectiveness currently! Likewise, have a look at our newest YouTube video on the FJD H36 Electric Motor Grader Control System to see the innovation in action: View now.

Throughout the years, we've seen operators with whole lots of experience do some remarkable things with their equipments. Perhaps they have an eye for changes that boost accuracy, or probably they know which features of their maker to utilize and when to increase performance or effectiveness - https://writeablog.net/sherozau/sheroz-earthworks-pty-ltd-and-sheroz-hire-pty-ltd-est. Yet with today's innovations in hefty devices innovation, also experienced drivers can gain from a real-time help to improve their everyday efficiency (trimble tripod parts).

This is where maker control systems aspect in. Some excavators come with equipment control systems that assist the driver through features to automate the digging procedure.

Sheroz Earthworks Can Be Fun For Everyone

With this added precision, rework is basically removed, allowing the driver to complete the project in a timely manner and relocate to the next task. For those working with dangerous or challenging jobsites, remote-controlled services open brand-new chances. This outstanding add-on allows you to run an excavator from a range in locations with harmful substances (like in a potash mine) or poor ground problems (like mud).

Machine control systems supply useful advantages to greater than simply excavator drivers. On-board weighing applications for wheel loaders, as an example, are prominent because several are so very easy to utilize. On-board considering makes quick work of precise filling. If you have actually a vehicle come in with a target of 23 loads, your driver can load their container and dynamically consider itoften without also being stationary.

This indicates the operator can see the specific weight of the lots they're about to unload (trimble parts). On-board considering offers real-time understanding into the container's load to make overloading, underloading, reweighing and waiting times a distant memory. Volvo Building and construction EquipmentIf they discharge 12 loads on the initial pass, the next pail needs to weigh 11 lots

3 Easy Facts About Sheroz Earthworks Explained

Most procedures make use of an on-board weighing app to make certain that the tons is precise before they send their vehicles to the scales, which is essential because the scale weight is what's used for invoicing and invoicing objectives. Several producers consist of some kind of considering program on their loaders. Some also have functions that allow firms to check and regulate the overall loads of multiple vehicles.

Report this page